black color laser marking on stainless steel, laser engraving machine YouTube

Stainless laser marking processes are common methods used in different scenarios. However, their use depends highly on the grade of stainless steel available and the use. Consequently, there are five laser marking methods for stainless steel marking. Laser Annealing/Stain Marking

deep engraving on stainless steel,30w fiber laser marking machine YouTube

power value for money And any unexpected surprises my tests revealed! (For non-metal laser cutting and engraving, we also have a general ranking on the best laser cutters and engravers) Top Picks CNCSourced Recommends Budget metal laser engravers for hobbyists Ortur Laser Master 2 Pro: budget pick but works on some metals

Stainless Steel CNC Laser Marking Machine, 2 Mm at Rs 175000 in New Delhi ID 20570812630

Our fiber laser machines can engrave or mark all types of metals including stainless steel, aluminum, tool steel, brass, titanium, and much more, allowing you to create a variety of mark types in no time!

Laser color marking on stainless steel,fiber laser marking machine YouTube

How you can use a laser machine to mark and engrave metals. With laser machines, soft metals such as aluminum or hard metals or alloys such as steel can be marked permanently, easily and quickly. The applications range from labeling for traceability to the personalization of promotional items.

Laser Marking on Stainless steel, PVC, Anodized Al from San on Tindie

Laser markers are user-friendly machines that produce UDI-compliant marks that don't wear over time or reduce the high corrosion resistance of stainless steel. In this article, we'll discuss UDI compliance, the challenges of stainless steel, and how laser marking is the solution. What is UDI Compliance?

20W Fiber Laser Marking Machine For Stainless Steel Marking Metal Laser Engraver Machine 2018in

With laser machines, soft metals such as aluminium or hard metals or alloys such as steel can be marked permanently, easily and quickly. The applications range from labelling for traceability to the personalisation of promotional items. Contactless marking process, without consumables or tool wear, ensures the lowest costs per marking.

20W Handheld Portable Laser Engraver Marking Machine with Battery for Metal Marking and

View Machine Open-Air Machine Robots used for multiple operations can be leveraged by opting for an open-air design, where the robot moves parts between stations and hold them during marking. This design easily supports multiple parts and cavities. View Machine Door Machine

100X100MM Portable Laser Engraving Machine For Stainless Steel , Laser Marking Device

Colour Laser Marking Stainless Steel In this guide we show you how to colour mark stainless steel, making use of the Wimbledon logo. This can be applied to bottles, nameplates, flasks, and much more. Replicating colours with laser marking can be a challenging process, especially if you are intending to get as close to the original logo as possible.

20W/30W/50W CNC LIVY fiber laser marking machine stainless steel laser engraving machine for

Selecting a suitable laser marking machine for metals can make an impactful difference in the success of your project. Depending on the type of material you are using, such as aluminum, stainless steel, iron, cemented carbide, copper or other metal composites, there are different processes and techniques that you need to consider to achieve the desired finish.

deep engraving on stainless steel,30w fiber laser marking machine YouTube

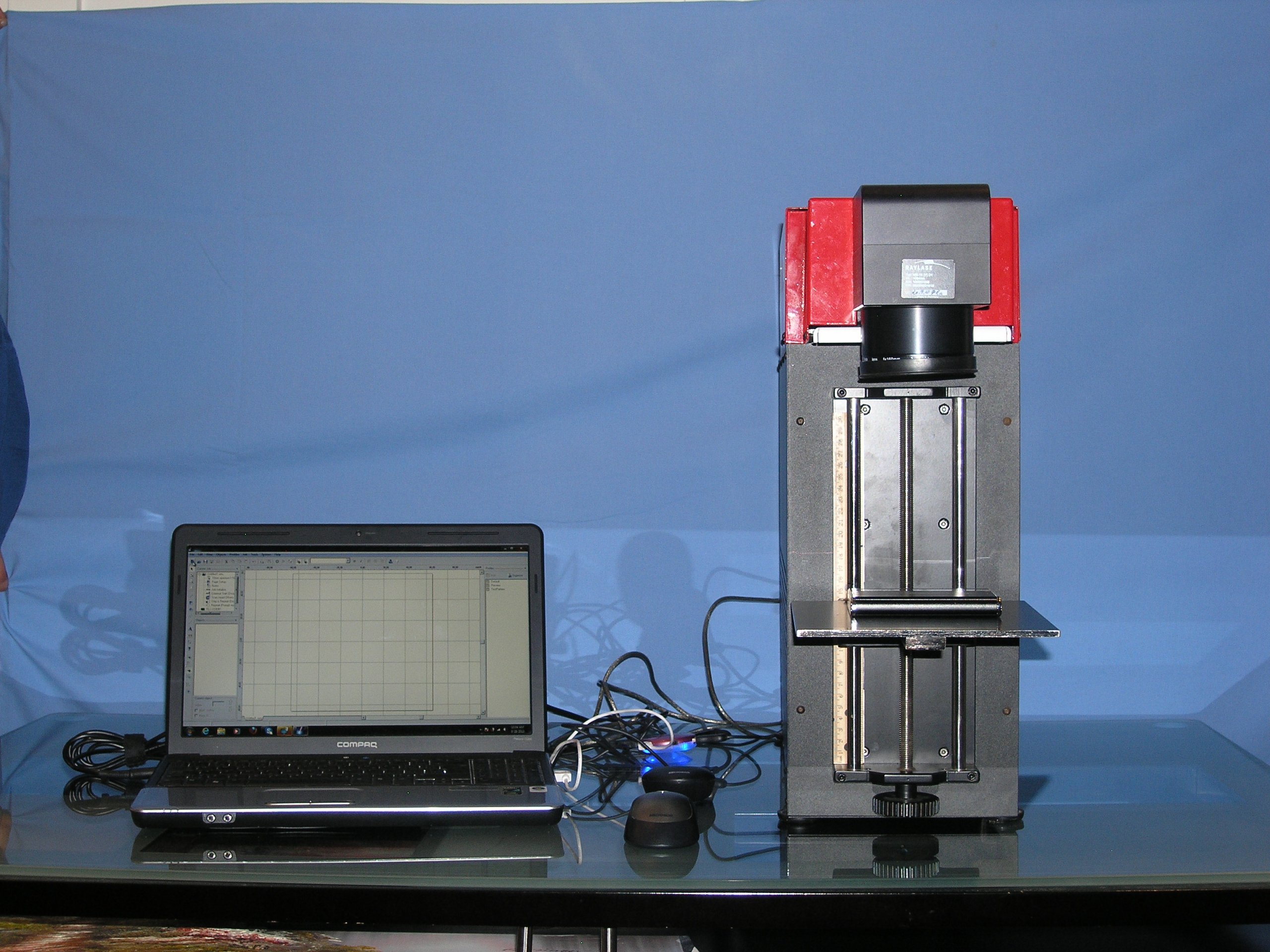

A fibre laser marking machine is the preferred system for laser marking stainless steel parts and surfaces. These laser systems are used to etch and engrave identification codes directly onto steel parts and on stainless steel plates that are attached to larger products. The laser marking process alters precisely targeted areas of the metal.

High Precision Stainless Steel Metal Laser Marking Machine

Laser marking on steel and stainless stee l is used both as a traceability method and for the aesthetic marking of logos and graphics. The laser guarantees indelible marks that do not lose quality over time. Whether using a traditional Fiber laser, or with its MOPA and Picosecond variants, we are guaranteed to obtain high-contrast markings.

Mini Stainless Steel Laser Printing Machine For Metal Sheet Laser Marking

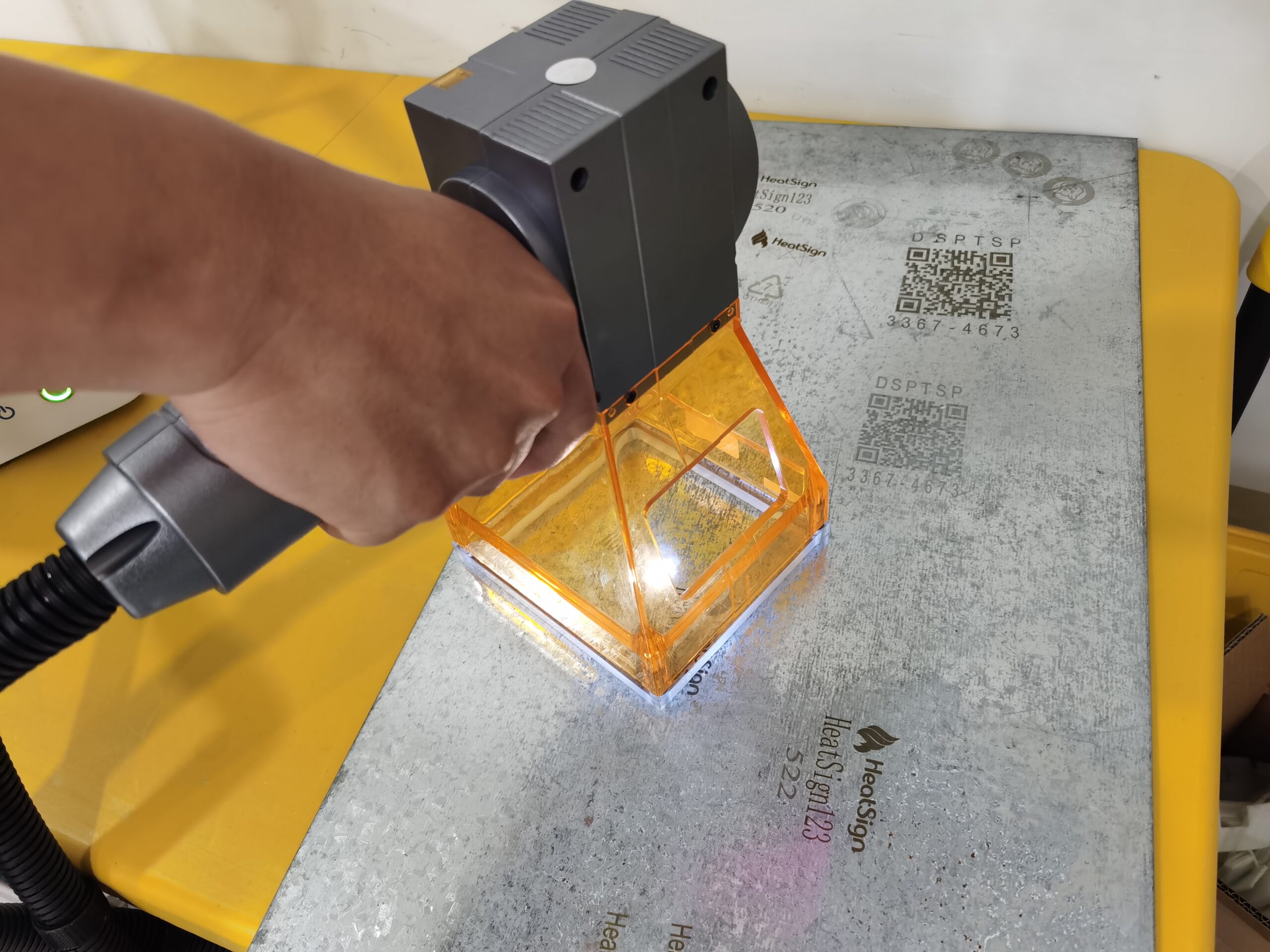

Laser marking, a non-contact process, involves using a highly focused beam of light to create markings on the surface of stainless steel. The laser energy interacts with the material, inducing a controlled reaction that results in permanent and precise markings.

Stainless Steel Portable Laser Marking Machine, Rs 330000 /unit ID 22594510648

Laser annealing is a marking process optimized for stainless steel. When used with a fiber laser system, it offers unmatched advantages for your manufacturing process. Permanent and Robust Marks Real traceability is only possible by directly marking parts. Laser annealing does that by chemically modifying the steel under the part surface.

Stainless Steel Big Size Product and Running Automatic Laser Marking Machine, ID 21969696488

Dual-Head Laser Markers APEX.200™ Vanadate Laser Markers UV Laser Marking Machines CO2 Laser Markers Class 1 Laser Enclosures. +1-740-477-5000. Dot Peen Markers. Laser marking machines for stainless steel can mark parts without removing their protective surface. Contact Telesis to inquire about our marking solutions!

Portable 20W Fiber Laser Marking Machine For Stainless Steel Marking Metal Laser Engraver

Laser marking machines are fast, reducing processing time. This leads to quicker turnaround and higher productivity in your work. Adaptability for Diverse Applications: These machines can handle different marking tasks, like serial numbers and logos, because they are versatile.

Laser Etching Stainless Steel With Fiber Laser Marking Machine

To get the best cuts when laser engraving, increase the power of the laser and decrease the marking speed. This ensures that the laser cuts more deeply on each pass, and with greater intensity, producing laser engravings that can withstand wear and tear on the material surface. 2. Be Mindful of Biological Traps created by Laser Engraving on.